Swabian ingenuity since 1919

Witness to tooling history

From a small cellar workshop to an internationally successful business concern, Bilz has been developing and manufacturing quality clamping tools with great success for 90 years.

Bilz stands for

- Success Concept Technical Partnership

- Flexibility and special solutions

- Excellent quality products

- 90 years of established industry know-how

- International network and market proximity

Bilz nowadays (2000-2011)

After the first intensive development projects with partners within the ThermoGrip® group, shrink technology became an established part of the Bilz clamping range from the year 2000 onwards. Today Bilz still plays a major role in shrink technology developments, for example as a member of the Standards Board.

In the year 2000 Bilz became a part of LMT (Leitz Metalworking Technology Group), a group of 6 medium-sized companies within the Leitz Group, each one a technology leader in their specific product area. Together with Belin, Bilz, Boehlerit, Fette, Kieninger and Onsrud the expertise of 6 companies is consolidated under the flag of an allround service provider.

After the Leitz Group was divided for company reasons in 2009, Bilz and Boehlerit remained part of the Leitz Group, while the other LMT partners became the Leading Metal Working Technology Group and became a separate group of companies.

For the customer nothing changed. The proven partnership between Bilz and Boehlerit in the sales network of LMT continues in the form of the strong alliance which exists today.

Product highlights from more than 90 years of Bilz quality

2010 - MQL, the next generation: Unique feature absolutely leak-proof

With the development of the optimized synchrofutters for MMS in joint project work with VW and alliance partner LMT, a technical milestone leap forward. Due to the high demand of the automotive industry, the new system will be transferred to the entire Bilz MMS program with immediate effect.

1998 - ThermoGrip®: starting shot for shrinking

Bilz formed the ThermoGrip®- Group together with partners Diebold, Marquart and Komet,. This group has had a considerable influence on the development of shrink technology and has maintained its leading technological position in the market with their patented taper and pole disc technology.

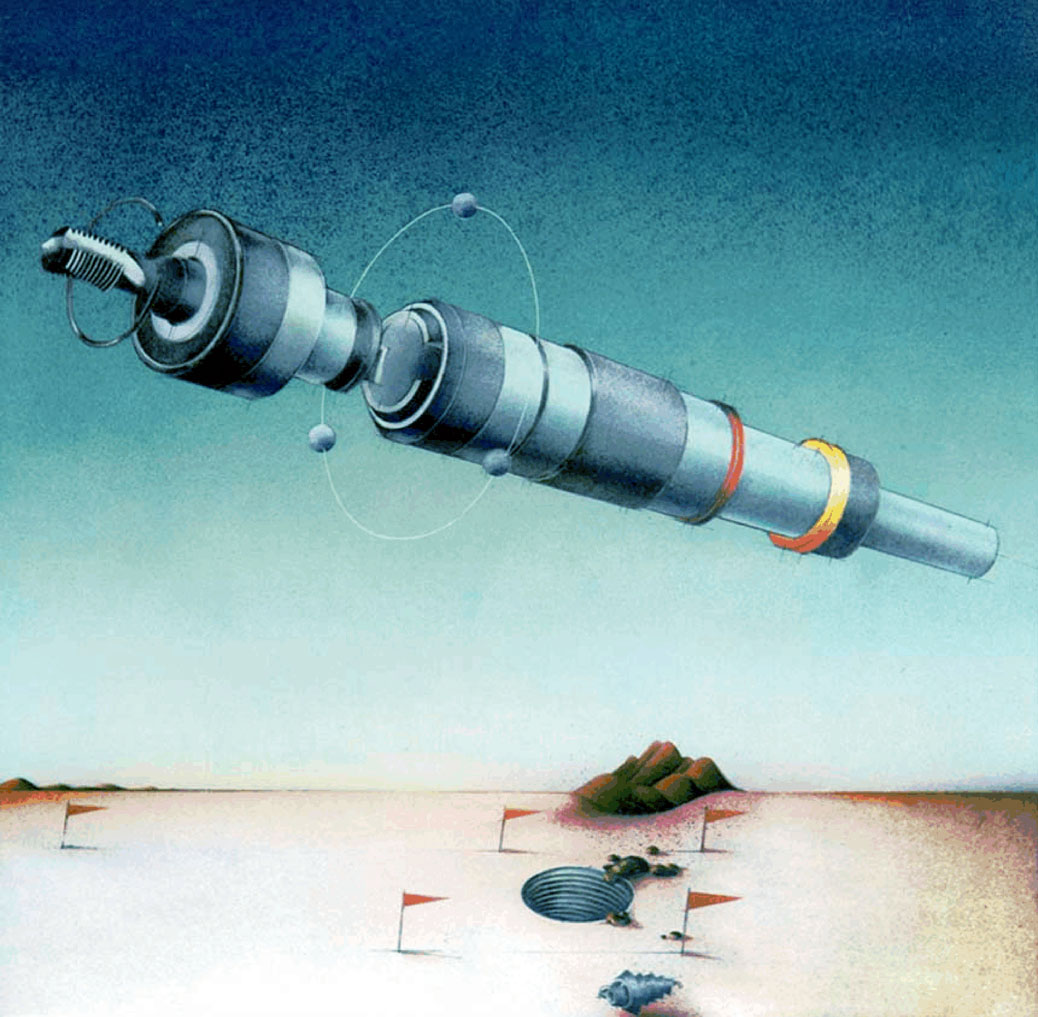

1983 - TDS: intelligent tool systems by means of a data chi

TDS – Tool Dialog System – this was the new dimension of tool identification and data transmission during machining centre operations. By means of an integrated data chip, the tools became intelligent. The system was brought onto the market in 1985 and the new generation arrived just 6 years later.

1960 - chucks for US NC-machines

The founding of an agency in Detroit was not only the successful move across the Atlantic for Bilz, but was also a groundbreaking step. Bilz was developing the first chucks for NC machines before these machines were even made or sold in Europe.

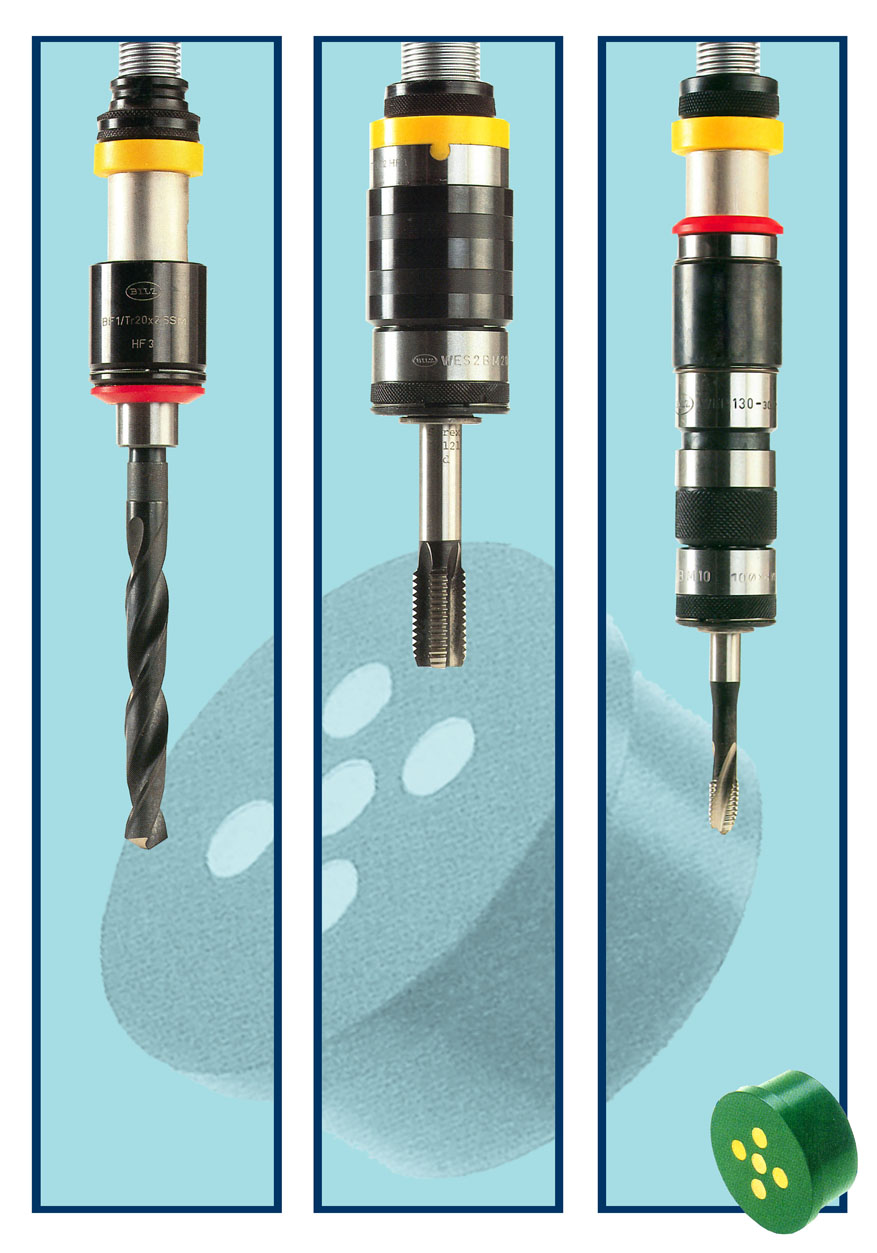

1950 - The worldwide first quick change system for multispindle machines and transfer lines

The introduction of the worldwide first quick change system was the big breakthrough for Bilz and was the result of close cooperation with Volkswagen Wolfsburg. Bilz was given the task of finding a solution to the continual problem of breaking taps, long change times and imprecise threads – and was successful.

1937 - First ever continuously variable square chuck

Following experiments with tapping chucks, Otto Bilz constructed a square chuck which could variably set different squares for the first time ever. The variable setting was achieved by means of four profile jaws driven by a spindle.

Expansion years (1977 - 2000)

Otto Bilz's death • Fimas • Morris Tooling • telerob • Mapal Bilz Preciosion Tools Ltda • Bilz France • Bilz India • Bilz USA

Following the death of Otto Bilz in 1979, his sons Reiner and Axel took over the running of the company. This was a time of many changes, both to personnel and to the structure. The company was expanding more strongly than ever before and an increasing emphasis was put on international partnerships. Most subsidiaries and partnerships were formed during this time. Fimas (Turin, Italy), Morris Tooling (Coventry, England), Bilz India, Bilz USA and Bilz France are still important customers today, as agents, distributors and even on a manufacturing level.

In 1996, the most significant partner project was initiated. In cooperation with Mapal, Bilz founded Mapal Bilz Precision Tools Ltda. in Sao Paulo. In the same year, the first manufacturing unit in India (Doddaballapur) was opened. Only three years later, external production was expanded to a second plant (3100 square metres) to meet increasing demands on space. In the USA, strong partnerships were formed – in 1997 Reynolds Machine Tools and Bilz founded sales and service centres in Chicago and Detroit.

Automation (1970-1998)

Process monitoring using HF transmitters • intelligent tooling • manipulator technology • group projects

1970 onwards: Bilz is at the forefront of the trend towards automation in production. Electronic HF transmitters in the form of data chips - TDS (1985), TDSi (1991) - make reliable process monitoring of the complete cutting process possible and are sold worldwide.

Bilz’s highest priority is progress through research and development and investments are made accordingly in all areas. For example, the fields of manipulator technology, robotics and telemetry (in cooperation with MaK System Gesellschaft, Bilz founded the company telerob). In cooperation with various partners Bilz worked hard to bind Bilz products into the technologies of the future.

In 1998, Bilz was also engaged in a group project within the framework of the Ministry for Education and Research. The research work on Microsystems for remote scanning of passive Surface Acoustic Waves sensors (SAW) at 2.45 GHz successfully advanced Bilz’s own development of wireless monitoring systems for multispindle machines.

Breakthrough years (1950-1964)

Development of the world's first quick-change system • Bilz chucks for US NC machines • New factory in Horb/Betra

With the of the worldwide first quick change system for multi-spindle and transfer lines Bilz achieved its big breakthrough in 1950, at home and internationally. Bilz ventured across the Atlantic and the American market showed much promised for the future. Cooperation with US companies resulted in the foundation of an agency in Detroit and a further innovative highlight: In 1960, Bilz invented the first ever chucks for NC machines – these machines were not even made in Europe at this time.

The company was also expanding on the home front. In 1964, the production and the workforce were expanded to the site in idyllic Betra, near Horb.

War years (1939-1945)

Enforced production programme for the Wehrmacht • new beginning with water taps • upturn thanks to the French occupation

In 1939 at the start of the War, the production range was compulsorily changed. Otto Bilz and his 20 employees were only permitted to manufacture for the Wehrmacht. Requirements were high and full employment up to 60 hours per week was the order of the day. The company expanded at this time and in 1943 Bilz was manufacturing at 4 different locations in Nellingen. Deliveries were made by handcart. Much to the regret of the young entrepreneur, the company’s own product range fell by the wayside.

1945 – War was over at last. Needless to say, the new start proved difficult. In order to gain new capital, the company (now in a much reduced form) started manufacturing water taps out of left-over materials in exchange for new materials. The first big customer is the French occupation force. Tools sets in large quantities were produced exclusively for the French, which helped the company get back on its feet again. After only two years, with drive, wits and hard work, Bilz was re-established on the market and had its own sales network for the first time.

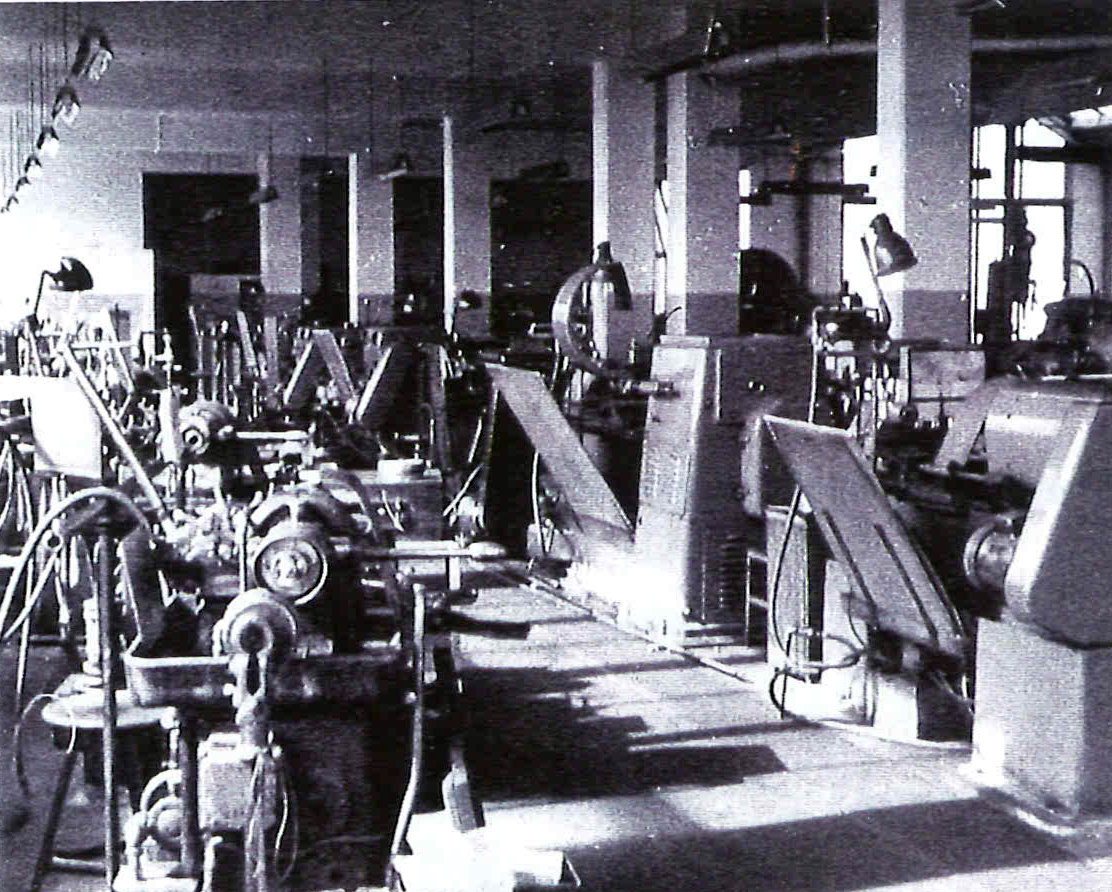

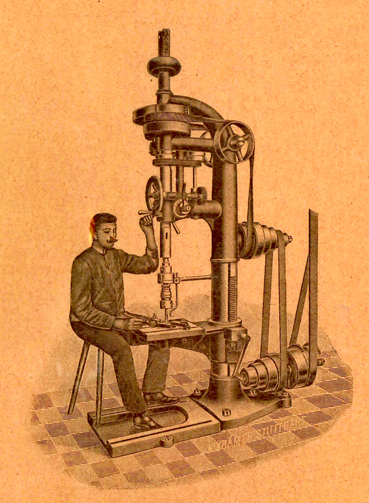

Foundation years (1919-1937)

GNCK forerunner OMAR • Ball turning machines • ratchets • pressurized air couplings • freely adjustable square clamping chucks

In 1919, Hermann Bilz founded the company Bilz in Nellingen. The small cellar workshop contained a lathe and a drilling/milling machine. The “Golden 20s” were an ideal time to start up, but were then followed by hard years of inflation. Despite this, the initial simple machining on commission was followed in 1924 by the development of the first independent product: OMAR, an early form of reverse gear technology and the forerunner of the present-day GNCK tapping attachments.

In 1929, Otto Bilz took over the company from his sick father as the sole owner. As a passionate inventor and entrepreneur, he set up his first own manufacturing programme, forged new business contacts and expanded the product range to include Bilz’s own invention ball turning machines, ratchets, air pressure equipment and valves. The products were sold through a distributor, Hahn und Kolb.

Today, ratchets and air pressure equipment are still part of the Bilz product range, albeit in a much updated and technically more advanced form, the result of 85 years of experience in the industry and technical know-how. The GNCK tapping unit is now used for high speed machining. Tests are being carried out at present on a new GNCK-HS version running at a speed of up to 100 metres/min. which is twice as fast as current market requirements.

Otto Bilz - company father (1903-1979)

Respected Inventor, salesman and swabian

Otto Bilz had a passion for inventing and was also a born entrepreneur. The young company had their first big breakthrough on the way to the top with the invention of the first quick change chuck worldwide in 1950. Innovation has been a central focus for the company right up into the present day.

Otto Bilz’s most important basic principles was the emphasis on customer orientation and constant contact to the customer. Up unto the present day, we make sure that we visit customers, exhibitions and production sites on a regular basis.

Early international contacts (1957 USA) made the development of chucks for NC machines possible before they were even built in Europe – thinking outside the box.

In times of increasing automation, Otto Bilz was able to stay ahead of the competition with innovations such as process monitoring using high frequency transmitters within the chucks.