Automation

Quick change system for industrial robots

Switch to fully automated processing with Bilz

Application

Application: Deburring, brushing, cleaning, polishing, grinding, drilling and rubbing operations

Machine type: Industrial robots

Features

- Fast automated tool change

- For tool and workpiece-guided machining

- Independent of the rotational position of the drive spindle

- Axial length compensation in using a compensating

compression range, optionally also avaiable with ten

sion compensation - Machine-side interface according to customer requirements

- Interchangeable with collet chuck as standard or individually adapted

BENEFITS

- Simple system integration

- Increased productivity due to reduced tool change times

- One chuck for different

application-specific interchangeable tooling - Use with drive spindles with low complexity

NEW:

Our AOCS Tool Storage System can be Equipped with sensor Technology!

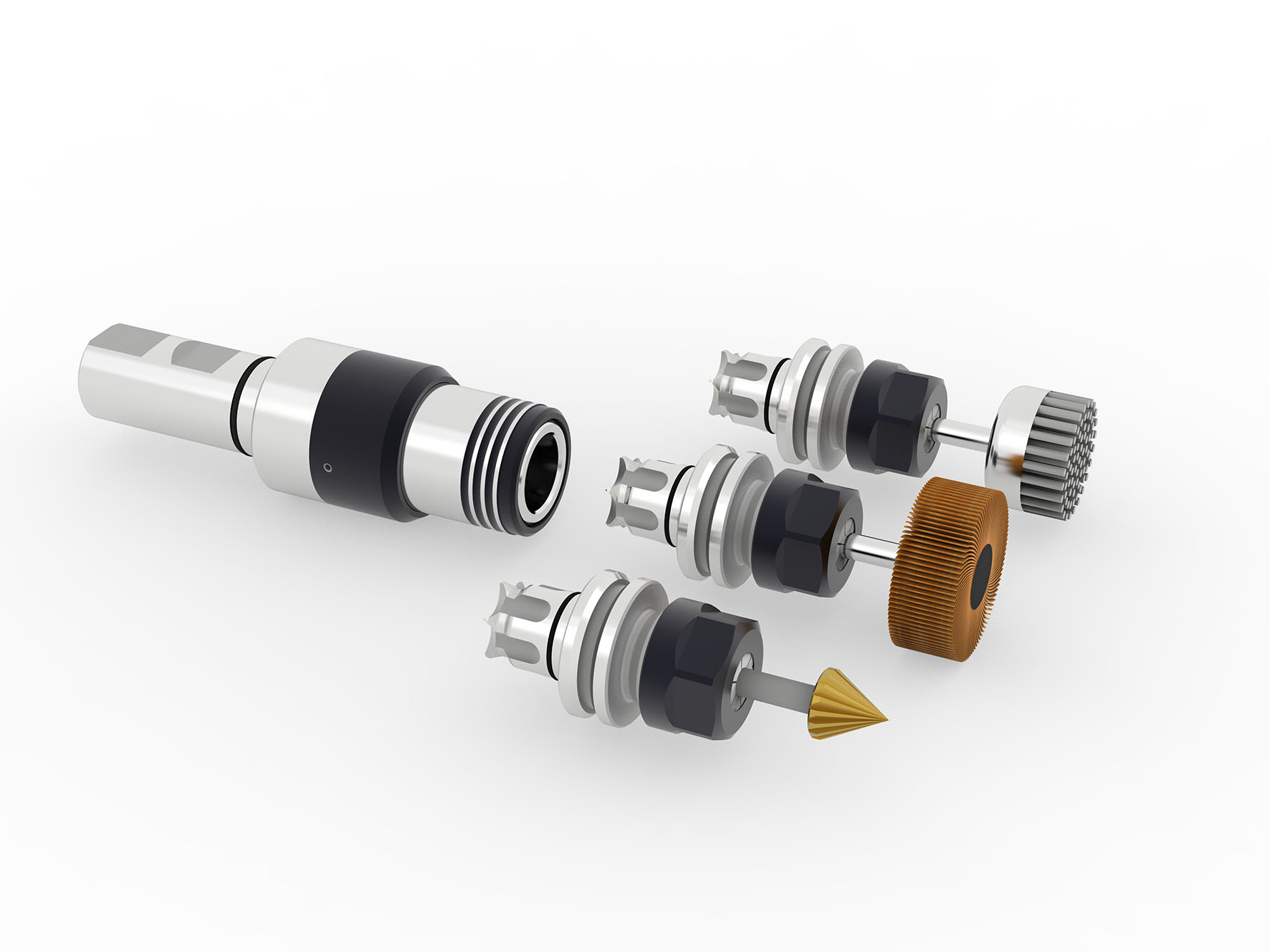

Precise, robust, simple to apply – The quick change

connection for reliable tool exchange

The AOCS (Automatic Orientation Clamping System) from BILZ enables fully automatic tool

changing when machining with robots.

Our AOCS change system from Bilz offers you a high degree of flexibility in your processing line

With the integrated system, tools can be changed fully automatically and without stopping the machining process.

This is a great advantage, especially for applications with relatively short change intervals. If a component has to be

machined with different tools to accommodate various materials , e.g. cast aluminium, magnesium or plastic housings,

a single spindle is usually sufficient.

How it works

The very high-quality AOCS system enables a position-independent tool change via a star-shaped coupling mount. The machine spindle,

for example, does not have to be positioned into a special fixture for this.

The tool-change is completed with the help of a special change station, this facilitates the pushing back of the coupling sleeve.

The spindle can be installed stationary or mounted on the robot.

Workpiece guided machining:

Used when the processing focus is on minimising

cycle times. AOCS supports you here with the

quick changing of worn tools with simple

automation processes.

Tool-guided machining:

The use of the AOCS quick-change system makes tool-guided machining

more beneficial: the advantages are the significantly smaller

moving loads and the reductioin of the working space.

The ability to change tooling successfully is the key factor for process optimisation.

The AOCS quick change system as a reliable and robust interface for automated tool changes,

reduces machine down-time thus saving valuable machine time. The quick-change system can be used independently of

the rotational positioning of the drive spindle and can load and unload the desired tooling for brushing, deburring polishing

and even grinding applications.

After reaching the magazine location, only an axial movement is required for tool changing

Movement in the direction of the interchangeable connection is necessary. Axial movement in the opposite direction

disengages the connection. The AOCS quick change system can be used in many ways, it supports your production with

deburring, brushing, polishing, grinding, and much more.

The interchangeable connections are available in three sizes. The chucking tools suited to ER11 to ER25 covers the complete clamping

range of cutters and tooling from 1mm to 16mm.

Chuck standard version

| Designation | max. load | n_max[min^-1] | Weight | Ident No. | Ø (mm) | Lmin (mm) |

AOC0-35-N-W16 | 10Nm | 20000 | 0,149 | 5163138 | 23 | 35 |

AOC1-40-N-W20 | 30Nm | 16000 | 0,290 | 5162467 | 32 | 40 |

| AOC2-60-N-W25 | 90Nm | 12000 | 0,827 | 5162477 | 50 | 60 |

Standard Chuck

Quick-change inserts

Designation | max. load | Ø | Lmin | Weight | Ident No. |

| AOA0-ER11M-25N | 7..14Nm (Ø3…Ø6 @ ER11M) | 17,5 | 25 | 0,038 | 5161418 |

AOA0-ER16M-40N | 10..25Nm (Ø4…Ø10 @ ER16M) | 22 | 40 | 0,067 | 5161419 |

| AOA1-ER16M-34-N | 10..25Nm (Ø4…Ø10 @ ER16M) | 22 | 34 | 0,090 | 5162475 |

| AOA2-ER25M-42-N | 30..60Nm (Ø8…Ø16 @ ER25M) | 40 | 42 | 0,342 | 5162475 |

Quick-change insert

Filing system

Designation | Weight | Ident. No |

| AOSZ0 | 0,149 | 5162292 |

| AOSZ1 | 0,290 | 5169202 |

| AOSZ2 | 0,827 | 5169203 |

| AOSZ0-S (with inductive sensor) | 0,149 | 5183130 |

| AOSZ1-S (with inductive sensor) | 0,290 | 5183136 |

| AOSZ2-S (with inductive sensor) | 0,827 | 5183137 |

Filing system

| Designation | Weight | Description | Location |

AOC0-55-N-S | 0,141 | Screwed into spindle | |

| AOC0-55-N-S | 0,096 | Screwed on to spindle | |

| AOC00-34-N-S | 0,052 | Screwed into spindle | |

| AOC0-116-N-S | 0,300 | Chuck with 10mm compression | |

| AOC2-61-K1-S | 1,188 | Clamped on Robot spindle | |

| AOC0-40-N-S | 0,104 | Chuck with hexagon drive | |

| AOC2-90-N-B16 | 0,808 | With "B" Taper connection | |

| AOC0-45-N-S | 0,083 | Screwed on to spindle | |

| AOC1-80-K3-S | 0,603 | With external througt coolant supply | |

| AOC1-80-K3-S | 0,153 | Clamping on motor shaft | |

| AOC2-78-N-S | 0,872 | Axial spindle clamping for shaft with parallel key |

At Bilz, we are proud to work with ToolDrives, a leading expert in the field of drive technology. ToolDrives stands for innovation, quality and reliability in the development and manufacture of high-precision drive solutions. With a comprehensive portfolio ranging from standard components to customised drive systems, ToolDrives enables seamless integration into a wide range of industrial applications.

ToolDrives' commitment to technical excellence and customer focus is reflected in every one of its products. By combining our know-how in quick change systems with ToolDrives' expertise in drive technology, we offer our customers comprehensive solutions designed for maximum efficiency, performance and durability.

Visit www.tooldrives.de to find out more about our partners and their innovative solutions aimed at optimising your production processes and increasing your operational efficiency.

![[Translate to Indisch:] [Translate to Englisch:] Bilz, Schnellwechselsystem für Industrieroboter](/fileadmin/user_upload/Bilz_Ostfildern__D-E_/Produkte/Sonderwerkzeuge_x/Schnellwechselsystem_fuer_Industrieroboter/Schnellwechselsystem_fuer_Industrieroboter2_BILZ.png)

![[Translate to Indisch:] [Translate to Englisch:] Bilz, Schnellwechselsystem für Industrieroboter](/fileadmin/user_upload/Bilz_Ostfildern__D-E_/Produkte/Sonderwerkzeuge_x/Schnellwechselsystem_fuer_Industrieroboter/Schnellwechselsystem_fuer_Industrieroboter_BILZ.jpg)