Bilz News

product information

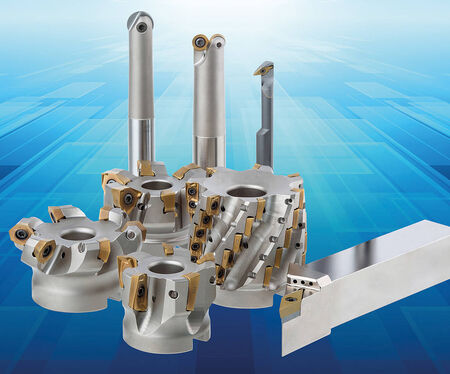

BOEHLERIT THE TOOL AND CARBIDE SPECIALIST

- Turning

- Milling

- Drilling

- Threading

For the product please click here

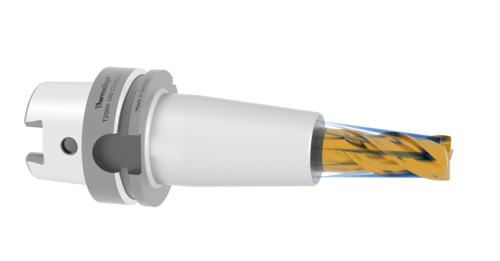

Thermal tool clamping meets Industry 4.0

- SAFETY

Automatic shrinking and cooling - TIMESAVING

Heating in seconds: the tool slides into the heated toolholder and is automatically centred in the BILZ

ThermoGrip® shrink chuck - SMART NETWORKING

TDSc reader and machine software implement Industry 4.0 in your processes and tool management

For the product please click here

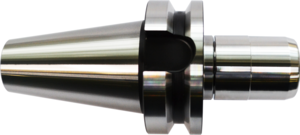

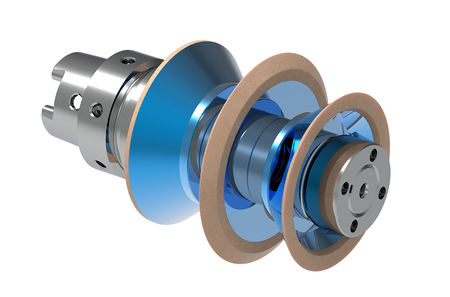

Grinding Wheel Adapter

- Our high precision wheel adapters can be offered with different length & diameter

- Wheel adapters can also be customized as per your requirement

For the product please click here

Super Collet Chuck

- Excellent Run-out accuracy within 5µ @ 4D

- Gripping force double than ER

- Integrated run-out accuracy with compact design

- Minimize the work interruption between tool and work piece

For the product please click here

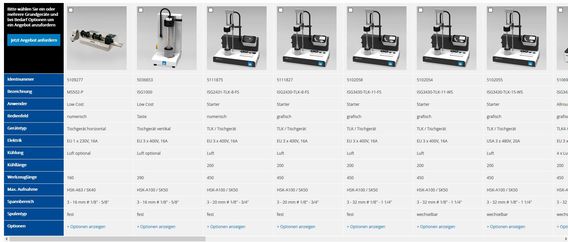

Configurator for shrink units

Configure your unit to match your requirements and ask for a personal quotation:

- All units at a glance

- Quick selection of all possible configurations

- For beginners and experts

For the product please click here

AOCS

With the Automatic Orientating Clamping System tools can be changed fully automated during the machining of tools with industrial robots.

- Makes clutching and declutching of processing tools possible

- Independent of the rotational position of the spindle

- Coupling can be effected via a tension or also via a shift sleeves

- Better sealing compared to actual quick-change systems

continue to the product and click here

STA Synchro Tap Adaptor

The new STA Synchro Tapping Adaptor was designed specifically for ER collet chucks and allows for synchronous thread cutting and forming to be archieved with all suitable machines.

- high productivity due to fast tool change times

- significant increase in tool life and process reliability

- reduced risk of tool breakage

- cost savings due to reduced tap inventory

- reduced spindle wear

- increase in process reliability

continue to the product and click here

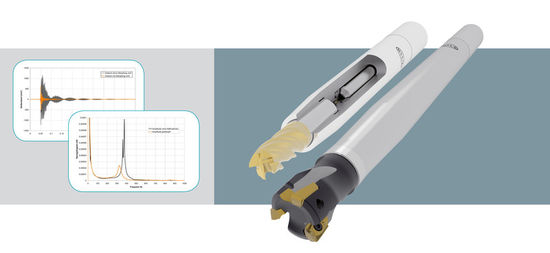

Expansion of the VIDAT programme for shell milling cutters

ThermoGrip® VIDAT stands for VIbrations DAmping Technology from BILZ

Vibrations caused during the first extension deflection are effectively absorbed by means of integrated dampers. VIDAT extensions achieve damping rates of at least 4dB in comparison to normal extensions.

The very rigid nature of the shrinking process means that long, slim extensions in particular have a tendency to chatter and vibrate. VIDAT extensions reduce this effect, thus considerably increasing the area of application.

continue to the product and click here

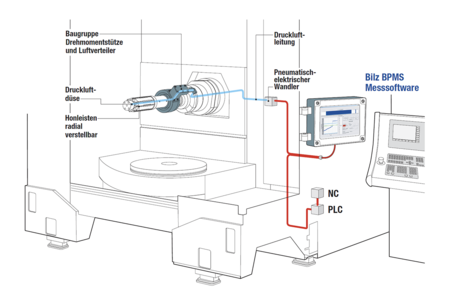

BPMS- Pneumatic Measurement System

System Structure for Process Meaurement

A fine machining process like honing is usually one of the last processing steps in the fabrication of forms, which includes certain tribology and dimensional precision properties. A precise control of the process is necessary. The measurement system from Bilz enables the integration of the honing process in machining centres. Honing tools with pneumatic measurement nozzles are required.

The recorded measured value, usually the diameter, is the criteria that is permanently compared to the requested size. When the measurement value is achieved, the interface communicates the value to the NC-Control which then stops the honing process. Because of this, there is no operator needed to monitor the actual hole size. The communication is made in 4 bit resolution over the PLC and up to 16 commands can be exchanged.

continue to the product and click here

Slim Hi-Power Milling Chuck

Bilz precision branches out into the traditional chucking world.

- Slim design helps to reach depth without fouling

- Powerful and rigid

- Clamping torque is twice that of ER holders

- Run-out consistency, 5 micron at 4D

- Clamping nut without slots makes its usage at higher rpm effortless

continue to the product and click here

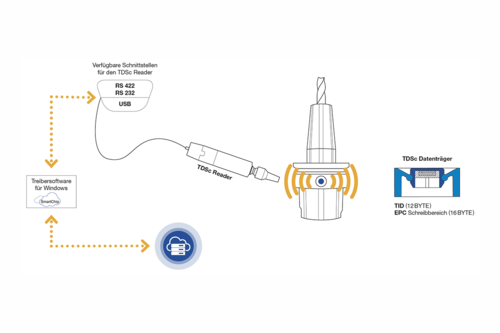

TDSc Data Carrier

ToolDialog Smart connectivity

RFID technology for modern industrial applications with industry 4.0 on our doorsteps, Bilz has developed an optimised and cost effective solution for in-process tooling identification.

Transmission in UHF-Range, ISO 18000-6

continue to the product and click here

Corona Jet

A new coolant supply through integrated inclined nozzles

ThermoGrip® Corona Jet offers a new coolant supply through integrated inclined nozzles which are aimed directly at the cutting edge. The dimensions of ThermoGrip® Corona Jet are identical to the standard shrink feed. On the end face of the nozzle ring, the tiny holes of the coolant outlet can be seen. ThermoGrip® Corona Jet like any shrink fit chuck can be used without assembling and disassembling. The tool holders are available in all standard lengths and many diameters.

continue to the product and click here