ThermoGrip® Slim Shrink Chucks

especially for the mold and die industry

Application

Application: induction shrinking of carbide tools

Machine type: for the mold and die industry

Features

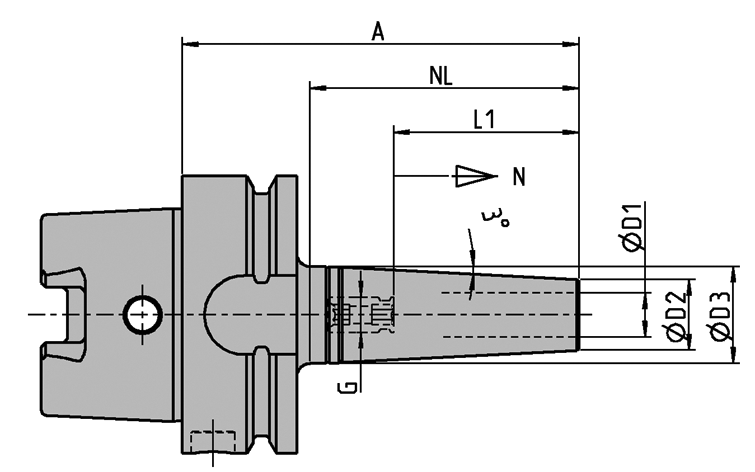

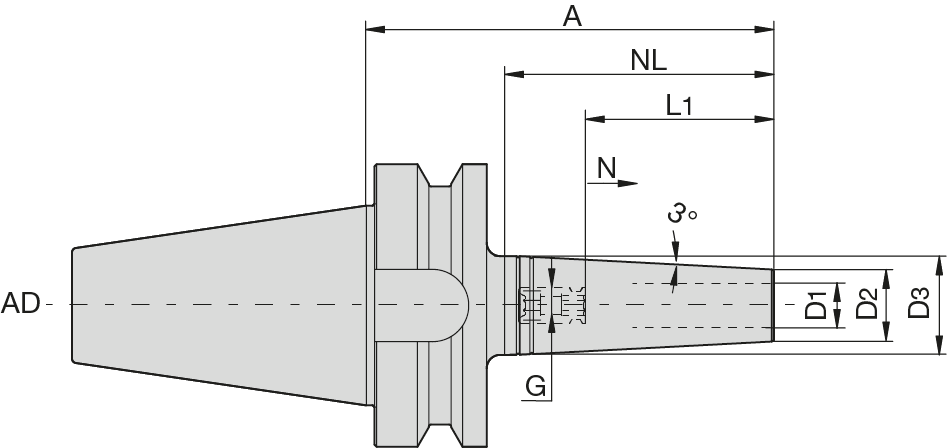

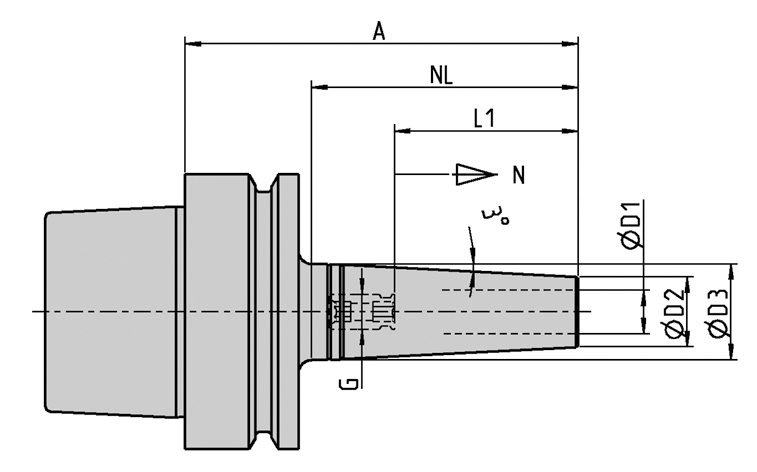

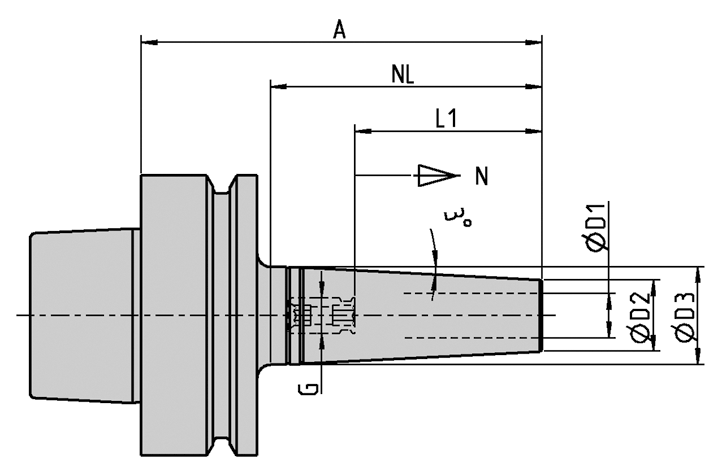

- 3° incline for overcoming the deep cavities seen in the mold and die industry

- Optimal combination of smallest possible interference contour, high radial rigidity and high torques

- Indication of the TSF geometry by 2 grooves

- Non-corroding coating for mold and die chucks TSF as well as all shrink chucks HSK-E and HSK-F

Advantages

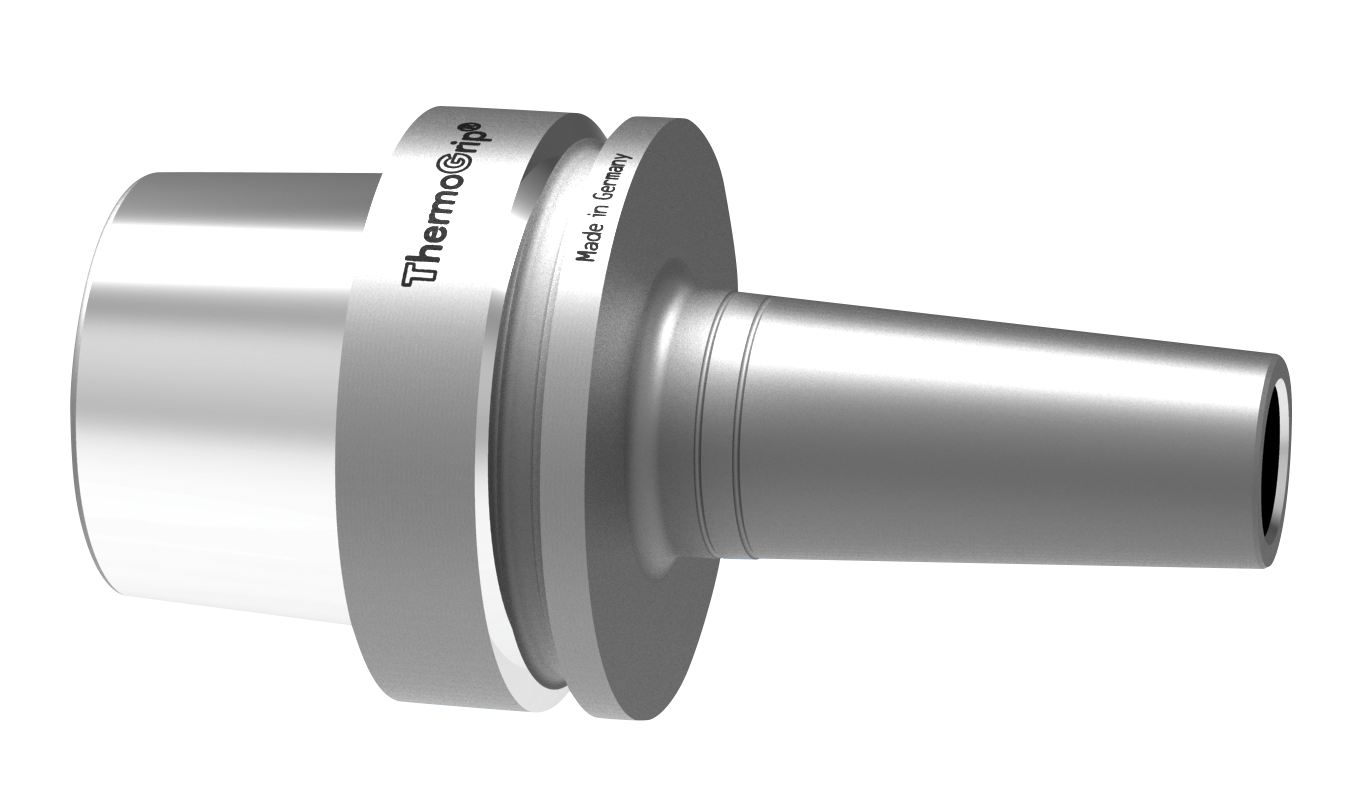

- Due to the slim shape of this new chuck, interfering edges are a thing of the past

- The slim shrink chucks also have a non-corroding coating

Description / Qualities

This chuck type is used for induction shrinking of carbide tools. Due to the slim shape of this new chuck, interfering edges are a thing of the past. The external geometry of the new shrink chuck TSF is designed with a 3° incline, compatible with dies and molds.

The slim shrink chucks have a non-corroding coating. The chucks have a concentricity of < 0,003 mm and are fine balanced at < 1 gmm/kg. Specifically for these slim chucks, all new ThermoGrip® shrink units are programmed with the parameters of heating time and generator output to shrink all possible shank diameters.

Older version shrink units can be upgraded with these parameters. As a result, thin-walled chucks can be shrunk with the highest reliability and without the risk of overheating. The broad product range means that chucks with different lengths are available for all applications on all standard spindles.