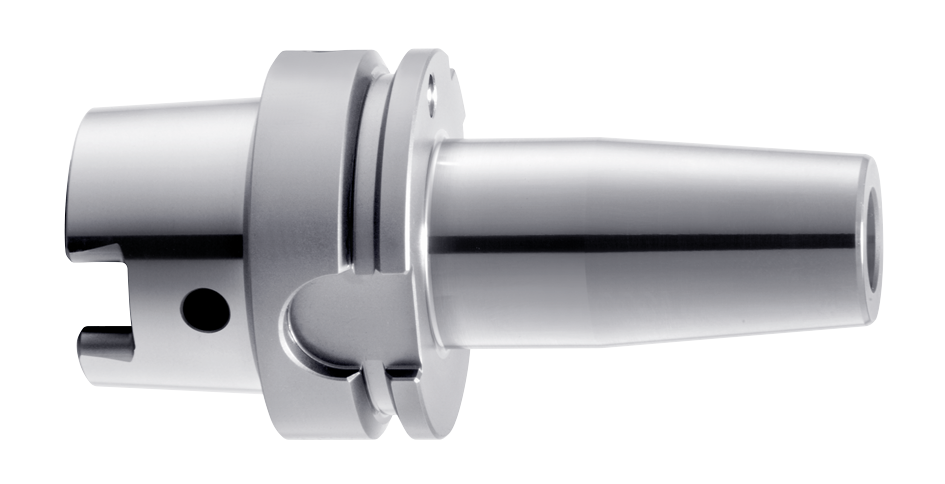

ThermoGrip® Shrink Chucks

Made in Germany

Optimized stability

through “Balanced by Design” and subsequent fine balancing

- Better surface quality

- Ideal for HPC/HSC processing

- Low wear of the machine spindl

Security

- All cylindrical shanks acc. to DIN 1835 Form A, B and E as well as DIN 6535 Form HA, HB and HE can be clamped

- No loss of clamping force on greasy and oily shanks

The patented counterbore

- allows insertion of the tool under cold conditions, as well as an automatic shrinking process and simplified handling

- 15 % – 20 % less heat required when heating the shrink chuck

Longest tool life

- < 0,003 mm and precise taper tolerances, manufactured in an air-conditioned production area

- Reduced tool costs due to improved tool life, allows a constant cutting edge contact

- Reduced chatter marks

Longest tool life

and form stability due to the use of high heat resisting, special purpose steel

- High radial rigidity

- Low deflection

- High rate of infeeds possible