ThermoGrip® TMG Shrink chuck

Extreme holding forces - Our new TMG is characterised by exceptional flexibility, high rigidity and optimised vibration damping.

APPLICATION

Application: general mechanical Engineering, Medical- and Dental Technology, Mold and Die, Renewable Energy

Features

- Constant maximum clamping forces

- Process-safe clamping of all shank tolerances

from h4 to h9Process-safe clamping of all shank tolerances from h4 to h9 - Anti pullout system for Weldon shanks

- Concentricity ≤ 3 μm

Benefit

- Increase of the metal removal rate

- Excellent damping properties Therefore better surfaces and better maintenance of tolerances

- One Basic holder for all diameters

M stands for Constant Maximum Clamping Forces.

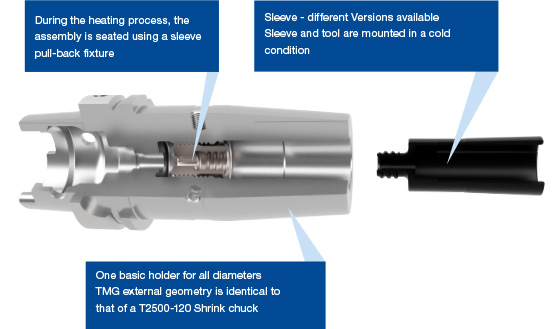

Due to the consistant maximum overlap of tool and chuck, the design ensures constant hight clamping forces. The sleeve is also available with pullout protection (Weldon).

M stands for added value.

For the first time, TMG clamps tool shanks of almost any diameter with one and the same shrink chuck. In this way, the entire production requirement can be covered cost-effectively. The flexibility of basic holders can be used to cover the entire production requirement.For the first time, TMG clamps tool shanks of almost any diameter with one and the same shrink chuck. In this way, the entire production requirement can be covered cost-effectively. The flexibility of basic holders can be used to cover the entire production requirement.

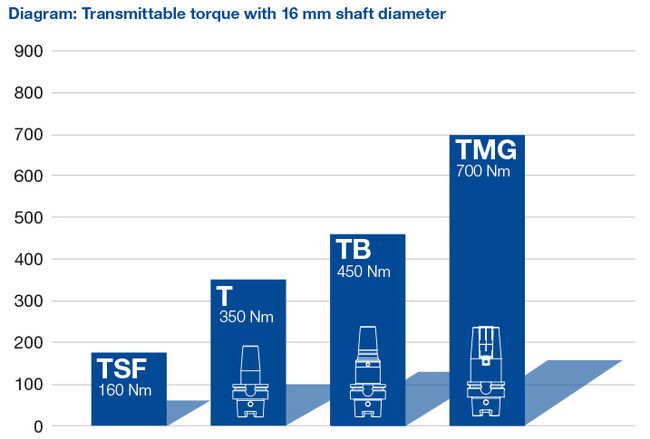

Transmittable torque with 16 mm shaft diameter

The new Bilz TMG clamping system combines the strengths of shrink clamping technology

with the flexibility of collet solutions. The system consists of basic holders and specially coated collets.

Shank tools from 2 to 32 mm can be clamped with previously unattained clamping forces. For example,

more than 850 Nm for a 20 mm tool shank. This is done in a fully automatic or manual patent-pending

process on induction shrink fit machines.

Manual shrinking

- Place the device in the shrinking position of the induction unit.

- Place the tool holder in the tool carrier of the device.

- Bring the tool holder into the clamping position by loosely turning the drive shaft anti-clockwise until the mechanism locks.

- Insert the collet chuck into the tool holder and screw it in by hand until a stronger resistance can be felt (approx. 3 turns).

- Insert the machining tool into the collet chuck.

- Select the appropriate shrink parameters according to the tool holder and insert the correct interchangeable disc.

- Start the shrinking process, whereby the holding time must be activated.

- After heating the tool holder, the machining tool is clamped by turning the drive shaft clockwise. The cooling process depends on the respective induction shrink unit.

Automatic shrinking

- Place the tool carrier and chuck in the shrink position of the induction unit.

- After selecting the shrinking parameters on our touch display and inserting the correct ferrite disc and coil, the shrinking process can be started by pressing the (Start) button.

- Insert the collet chuck into the tool holder and screw it in by hand until the elastic stop can be felt (approx. 3 turns). The collet chuck only needs to be applied to the axial stop with a low torque. The tool can then be inserted into the collet.

- The shrinking process is continued by pressing the (start) button.

- With the ISG3460-WK, the shrink chuck is lowered into the cooling unit and then the coil is raised to the upper end position. After the cooling time, the chuck is slowly moved upwards and dried with compressed air. It can now be removed by the operator

The new Bilz TMG clamping system combines the strengths of shrink-fit clamping technology with the

flexibility of collet chuck solutions. The system consists of basic holders and specially

coated collets.

Secure clamping and unclamping is carried out in a fully automatic or manual process

on our induction shrink units from the ISG3XXX series upwards. Both the shrinking process and the

and the associated chucks are patent-pending and only available from us.