Nano Synchro

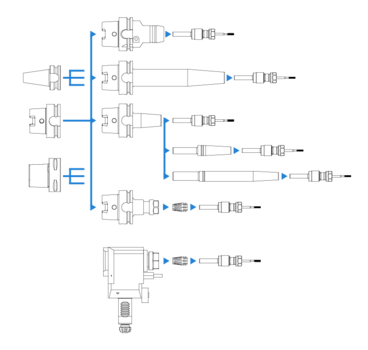

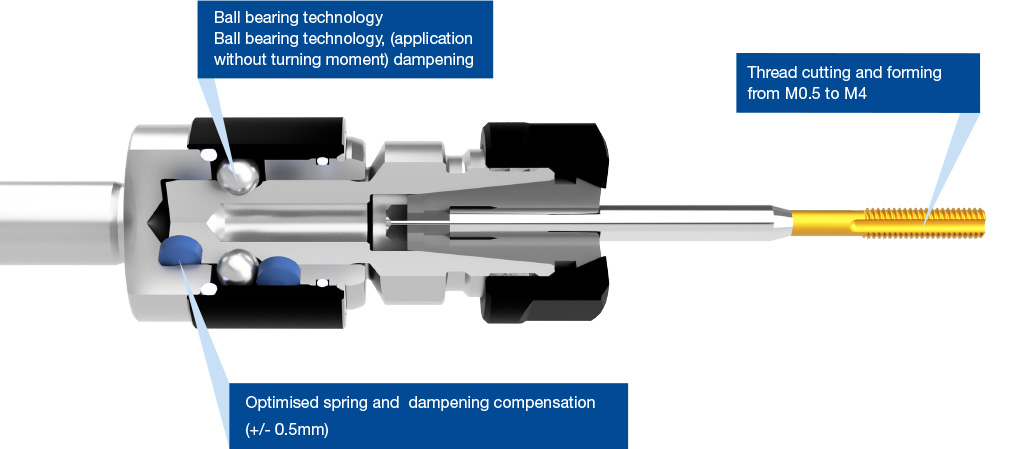

Tapping with both, „Forming and Cutting taps“ M0.5 to M4

Area of use Application

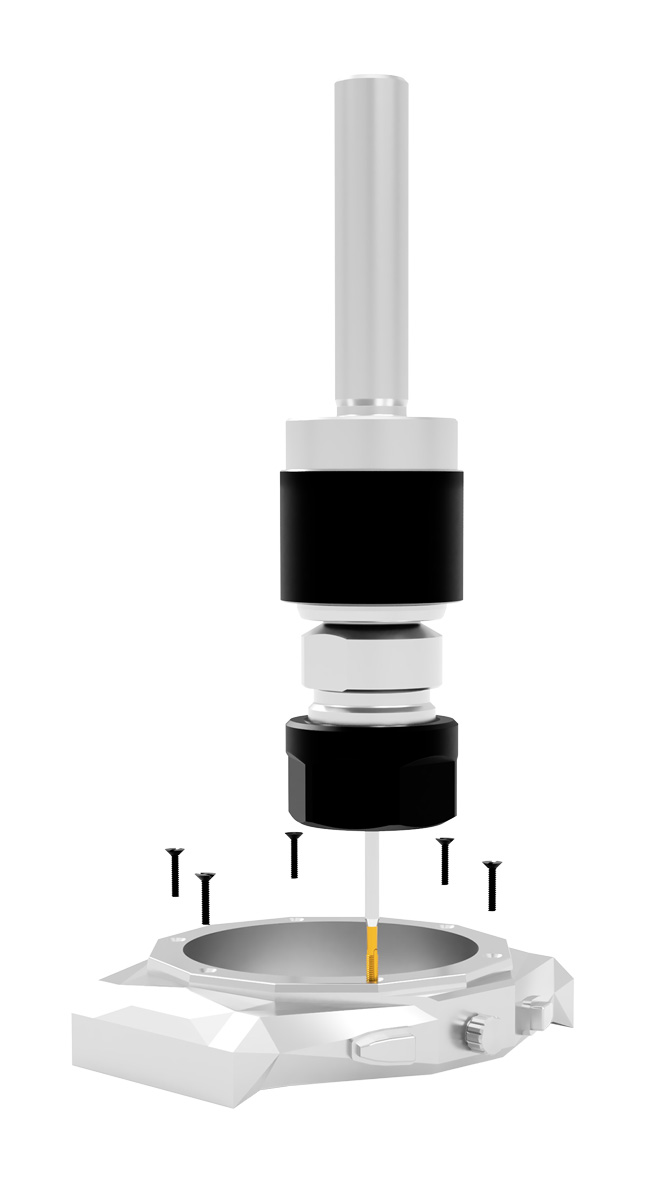

Application: electronics, optics, precision mechanics, toolmaking

Machine type: Machining centres, CNC lathes, special machines with synchronised feed for thread cutting

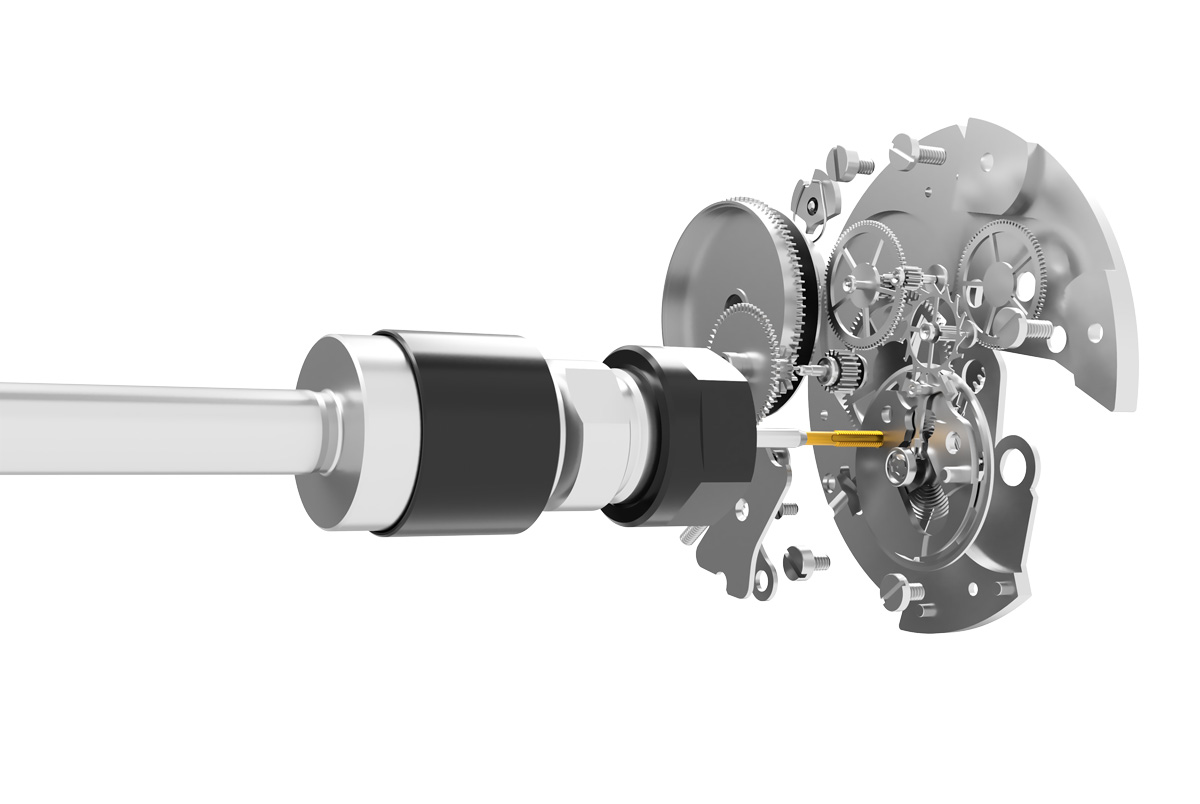

Features

- Minimum tension and compression compensation

- Ball bearing technology, (application without turning moment) dampening

- Suitable for cutting and forming taps

- Suitable for right and lefthand threads

- Optimised spring and dampening compensation (+/- 0,5mm)

- Suited for external coolant supply

Advantages

- Highest process stability

- Extended tapping tool-life

- Improved thread quality

- Reduction of thread flank cutting pressures

- Compensates spindle synchronisation errors.

Finest technology in highest precision

Extreme short build size, 80mm overall length, this reflects the same build-size as previous synchro chucks, (no reprogramming necessary).

Highest technology precision for your applications.

Contact